Biocracking of Hydrocarbons

In today's refineries, cracking is performed with various technologies and at different parameters of temperature and pressure (up to 850C and 70bar), with or without catalysts. All very energy consuming—refineries today spend 7% to 15% of the crude oil feedstock for their own operations, mainly heat generation [https://www.sciencedirect.com/science/article/abs/pii/S0360544206002416]. The resulting products keep us on the road, in the air, moving at sea, and are the base feedstock for thousands of other, non-fuel products.

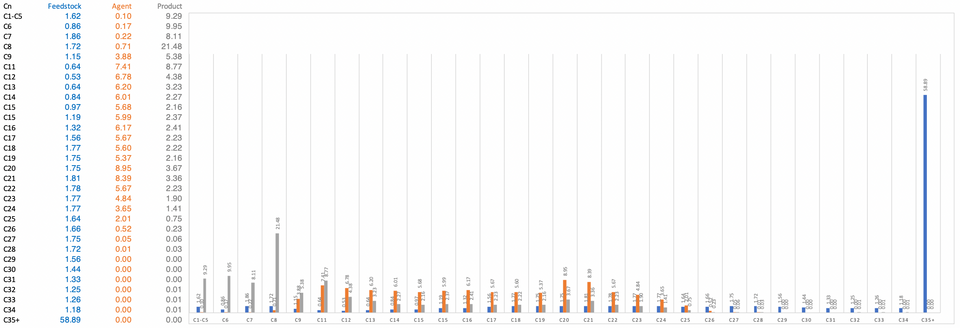

Our biocracking technology now works under almost ambient conditions and the active biological process drivers are self-propagating—thus this processing requires very little external energy supply. The lab test results above show how the heavy alkanes C35+ have vanished and the light ends in the gasoline range (C4 - C12) increased drastically. Note that this is the result of just a few hours; the generation of light ends can be maximized by extending the reaction time (think of hours).

See here what conventional refineries make out of the petroleum received https://www.eia.gov/dnav/pet/pet_pnp_refp2_dc_nus_mbbl_m.htm. The first opportunities for our tech lie in the process tail ends, i.e. residuals of various kinds upgraded to low price products, e.g.: residual fuel oils ("RFO") with >1%m sulfur—almost 4 million bbl/month in the U.S. alone! All it would take is processing of that residuum with our technology, followed by atmospheric distillation and most of the RFO would become gasoline constituents (with high RON!).

And this is just the beginning...

Member discussion