Reservoir Bitumen Mobilization

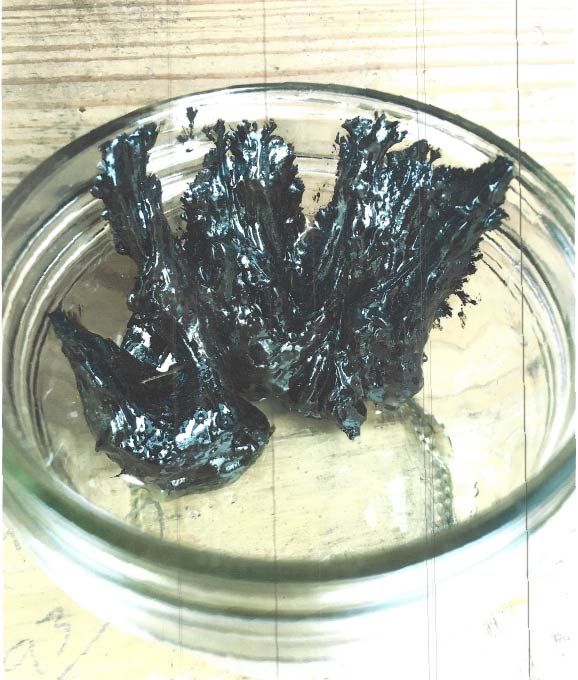

(Super) Heavy crude oil with low or zero mobility is referred to as bitumen, or when comingled with sand, oil sand or sometimes tar (although "tar" is better avoided as this term is used already for something else). The problem for production is first and foremost that bitumen has very low kinematic viscosity, i.e. it can't be pumped (lifted) without liquifying it first.

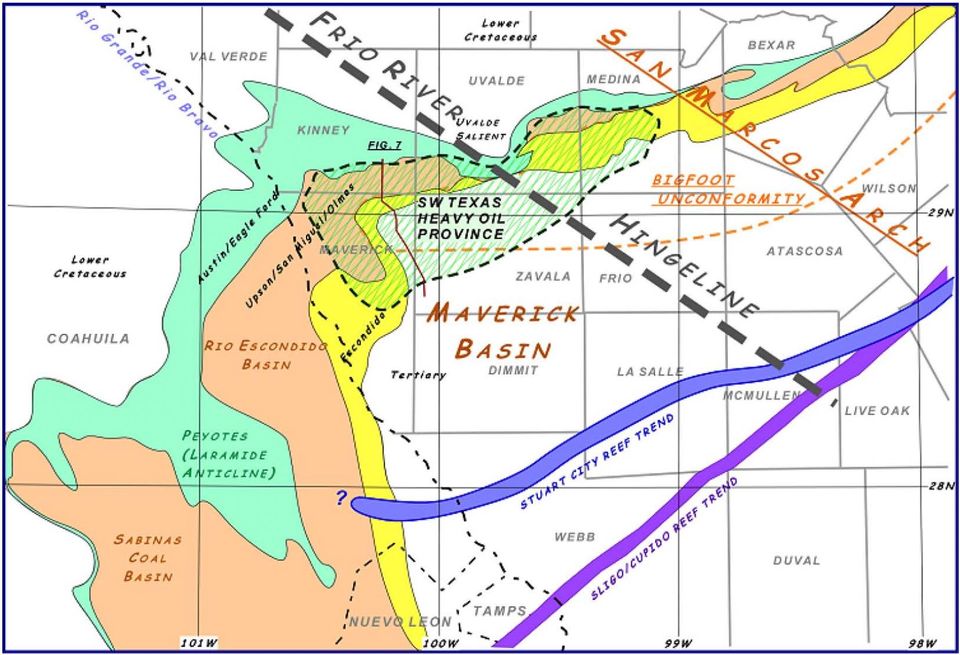

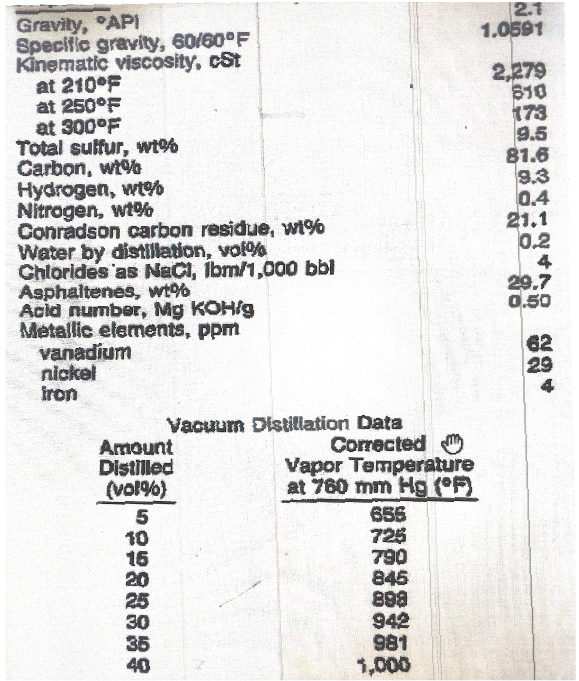

This bitumen has heavier properties than the Canadian oil sands by a long shot, e.g. double the sulfur concentration. And it is found at depths of > 500 meters, prohibiting open pit mining. Many attempts have been made by various parties over the decades to get this bitumen out of the ground, but sooner or later all gave up. Newer published in-place numbers indicate a volume of 7-10 billion bbl, huge!

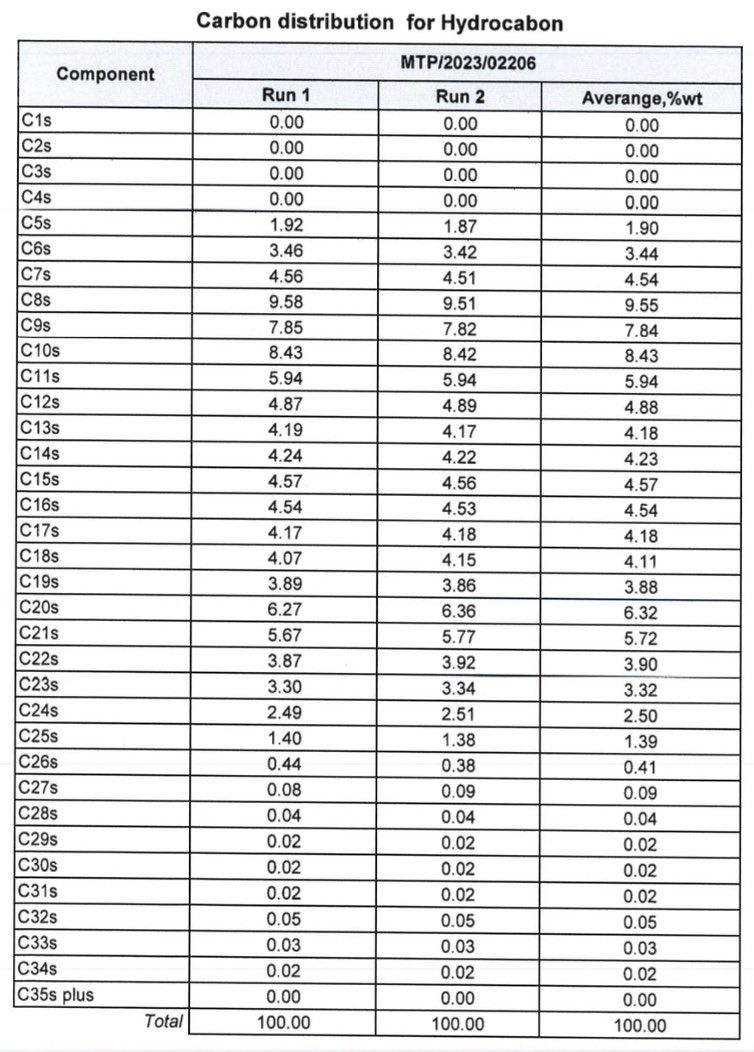

We have performed tests of our technology on original San Miguel samples. The results are excellent―within a couple of hours, a sample at estimated reservoir temperature was transformed into a medium viscosity mixture with good mobility. But this could also be achieved with mechanically enhanced dilution (shaking the bottle), so what is the proof that our technology is more than just that? Here: The viscosity reduction is the result of our biological agents cracking long hydrocarbon chains:

Alkane carbon chain lengths in treated San Miguel bitumen

The untreated feedstock is at best guess believed to have > 50%m of C35+ carbon chains, they are all gone. And this is how mobility of the bitumen was achieved. A short video clip before and after treatment can be found here: https://ln5.sync.com/dl/99a222010/rugv57y5-hx5455mr-awnpkjya-d2aj5s6v

We believe this is the way to get this crude out of the ground and look for suitable partners and opportunities to try in situ.

Member discussion