MIDSTREAM

Pipeline / Transportation:

Frequently

transportation issues occur in pipelines for heavy hydrocarbons due to their

high viscosity and deteriorating quality.

We use the

agent to reduce the viscosity within a short time and make the crude oil

pumpable again. There is no longer the need of any problematic chemicals or

other expensive diluents. These can be replaced by our fully organic

bio-chemical process.

Our

customer has confirmed that the viscosity can be reduced both quickly and

economically. Currently we are already working together on several sites.

Principle of viscosity reduction…

Oman

Reduction of Viscosity

Introduction:

Our customer has conducted various tests with our microbial agent and our defined process.

These are their statements:

"This test focused on viscosity depression as the primary treatment target in order to facilitate truck and pipeline transport; however, laboratoty analysis also extended to the underlying functional mechanism of microbial cracking.

Viscosity: The original target was to work with kinematic viscosities. This proved impossible for the before-treatment crude sample due to its exhibited non-Newtonian behavior (shear rate dependence), which appears to originate from the 11% by mass ("m%") water content of this sample.

Discussion of Results:

- The viscosity reduction target was <900cSt at ambient temperature (Oman desert).

- The shown carbon distribution comparison demonstrates the cracking of heavier hydrocarbon molecules into shorter ones as the driving reason for the viscosity reduction. This property upgrading is an inherent benefit of the technology and increases the crude quality E.g., decane went from 1.38m% before treatment to 7.55m% after treatment, an increase of 447%. This proves that this is not a simple dilution by the agent.

The same

customer intends to apply this principle for other applications, like oil

sludge from tanker cleaning.

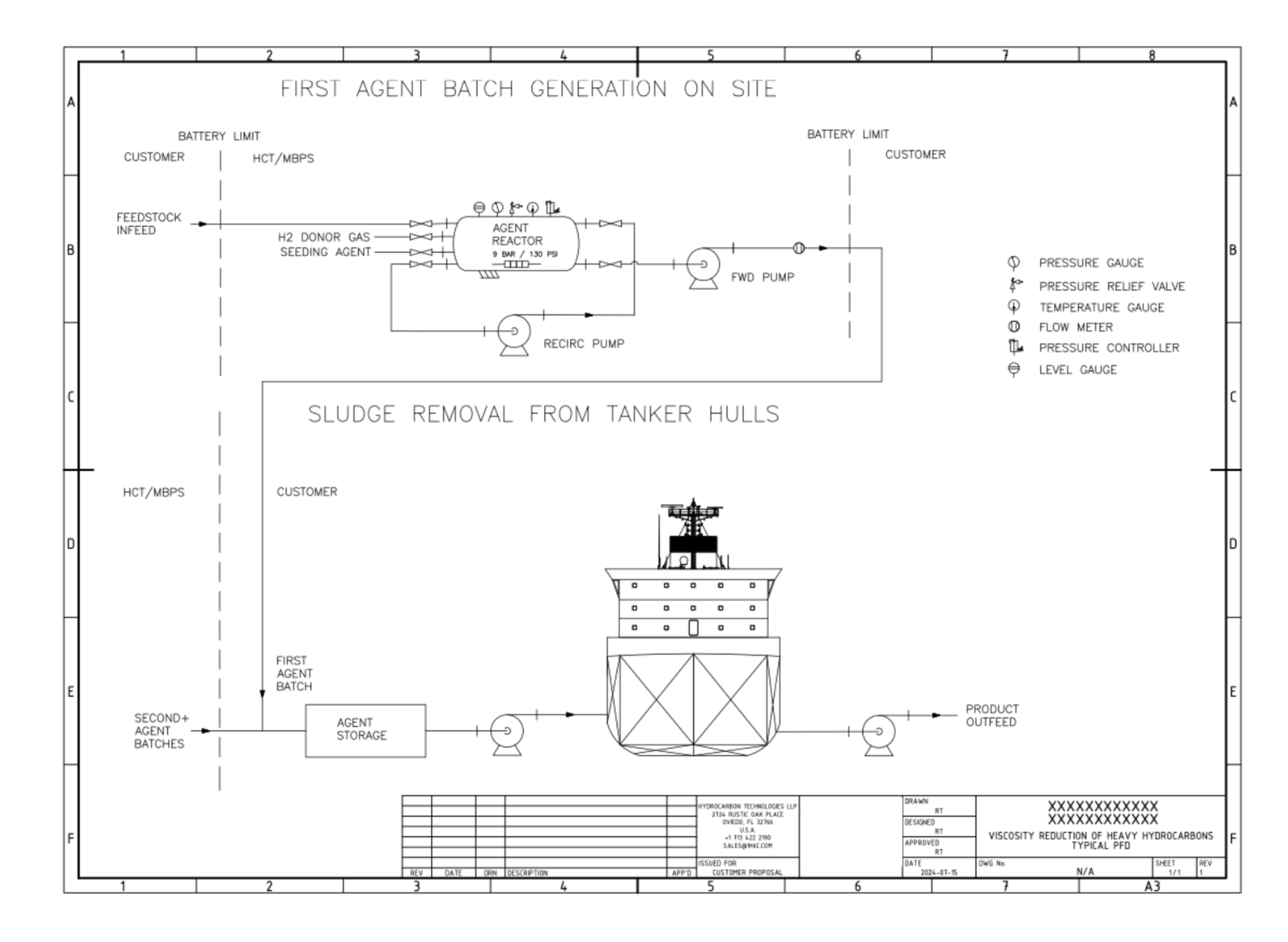

Tanker /

Tank Cleaning:

Cleaning and

extracting of oil sludge in tanks are costly and highly time-consuming.

Additionally, this work takes place under hazardous conditions.

We use the

agent to reduce the viscosity and to transform the sludge into pumpable lighter

hydrocarbons that are ready for further processing.

We expect a significant more profitable and much faster process. The output of the process are no longer waste hydrocarbons but upgraded, light ones.

Application

for Oil tanker cleaning...

We expect the following direct business benefits: